DIY Master Audio Stepped Attenuator A/B Switcher

Last Update 08-15-2025

This DIY stepped attenuator became a necessity when I wore out the

master volume control on my line mixer to the studio monitor

speakers. That part is no longer available so I stopped using

those master volume controls. The attenuator is the stepped

type that includes compensation of frequencies according to the well

known Flescher-Munson loudness curve of the human ear. The

multi-ganged 24T4P rotary switch (4 poles for stereo balanced lines)

will last much longer than those volume controls.

The A/B switcher became a necessity because my studio had grown such

that I have two locations from where I build songs. One is the

MIDI station where all my keyboards, modules and DAW computer are,

the other is at the Mixing station where the mixer, hard disk

recorder, and processors are. Most studios would use two sets

of monitor speakers; I only needed one set because the speakers

rotate at the keyboard stand, pointing to where I am working.

The keyboard stand with speakers is strategically placed so they are

close to the near-field listening range of the speakers whether I

work at the MIDI station or the Mixing station. Saves wiring,

and saves the expense of an extra power amplifier and speakers.

Picture the A/B switcher as a 2x2 matrix switcher, with console

input/output on one axis and keyboard/monitor on the other

axis. All I/O are stereo balanced differential lines. I

need two configurations for the switcher. One is when sitting

at the Mixing station I want keyboard outputs routed to inputs on

the mixer, then mixer outputs routed to the monitors. The

other is sitting at the MIDI station, I want keyboard outputs routed

to monitors and no mixer routing.

For clarity I used chrome plated jacks for stereo left and black

ones for stereo right. A single rotary switch does the matrix

switching. The matrix relative to the rotary switch is

actually 8x8 - 4 sets of stereo L/R lines each which are dual

balanced differential wires. Thus I acquired a 8P2T rotary

switch for the job, break-before-make as I wanted to avoid any

feedback loop squeal between switch states.

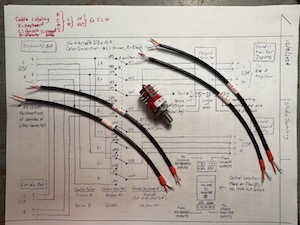

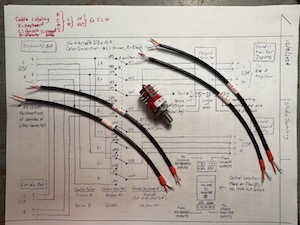

In the image above, rotary switch and sample cables are shown before

assembly. Cable prep involved not just trimming the wires but

labeling the cable, so that when the jacks are connected I know

which ones are which. The raw cables are Canare L-2B2AT that I

acquired from Redco. It is lightweight low profile cable for

fixed installations (IE rack wiring) and is very easy to work

with for assembly. I have been using that cable in my studio

and stage systems for over twenty years and have yet to find a

broken cable. I have a long established convention of wiring

the white wire to pin 2 (hot) of the XLR interconnect and the orange

wire to pin 3. To avoid ground loops I do not route shield

(shield wires are not "ground" and only need connection at one end)

or chassis on the jacks (shield from the monitor amp is used for

ground at the attenuator network circuit). This keeps

everything straight and retains the hair on my head!

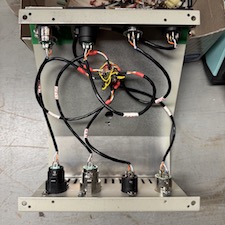

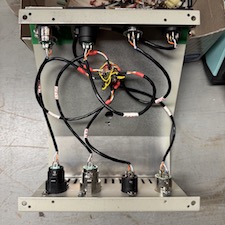

The next image above is a close-up of the wiring of the rotary

switch. This is where I had to be really careful against

wiring errors, and there were a few occasions I caught myself making

an error. I used shrink wrap tubing at the switch terminals to

minimize flexing of the wires and prevent breakage. Not

anxious to fix a broken wire in that rats' nest!!

Next image shows the assembled matrix switch box (I have not yet

assembled the stepped attenuator). The jacks had to be

oriented upside down or sideways (hey I didn't design this thing to

be pretty) so with the hood open I could access the set screws that

secure the connector inlet. These inlets need to be removed

for wire assembly. Next is testing - it worked right out of

the gate. Preparation is a big part in assembly!!!

The next project is building the stepped attenuator assembly, which

will be a bitch but there were good reasons for this choice. I

chose the stepped attenuator design that I found in one of my

engineering books (Audio Cyclopedia by Howard M Tremaine). The

attenuation network is not only a multi-tap voltage divider it also

includes filter networks to simulate the Flescher-Munson loudness

curve that maps the relative loudness of the human ear over the

frequency range. The frequency response of the human ears

between loud and soft volume is not flat!

Why not a simple variable potentiometer? It is bad practice to

use a variable potentiometer for stereo volume control - this

requires a ganged audio taper potentiometer. The forming of

the taper of each gang layer is not consistent from layer to layer

during fabrication so there is no guarantee that all mechanical

positions of each layer will be the same resistive value. Bad

news with differential signals as this will cause stereo image shift

and alter the tone of the signal (big no-no in a studio). And

we're asking precise attenuation with balanced signals of stereo

pairs, requiring four ganged potentiometer - forget it!

By using precision resistors and tight tolerance capacitors in the

attenuator networks, the attenuation between all four signals is

consistent enough that image shifting will be minimized. The

human ear is not sensitive to volume differences, the best it can

detect is a 2dB change. The precision of this attenuator

network from gang to gang is 2dB. The metal film resistors are

military grade low noise types, same ones used in professional audio

equipment. The polystyrene capacitors have a very low

temperature factor, meaning their values vary the least over a wide

temperature range. These capacitors also have low absorption

factor meaning that they drain almost all their electrical charge

when they are discharged. To minimize image shift in the

stereo field, these are important parameters for critical tuned RC

networks such as multi-ganged stepped attenuators especially those

with non-linear frequenty contours.

Stepped attenuators are found in professional audio devices and

broadcast systems. The stepped attenuator has one big

disadvantage - it requires a 20+ position rotary switch with four

poles. These are not easy to find and they are not

cheap. Fortunately I happened upon a NOS supply of 24T4P

rotary switches so I bought a few to last me for life. As a

bonus, the switch contacts are sealed and gold plated for maximum

conductivity. Rotary switches enjoy one big advantage over

variable potentiometers - they have a much longer life.

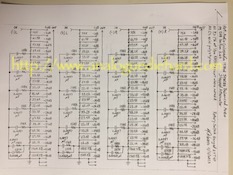

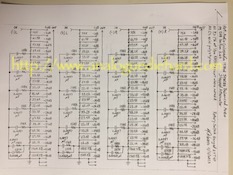

Assembly of the stepped attenuator is going to be a bitch. In

the 2nd row of images above, the rotary switch and bins of

resistors/capacitors are shown. The attenuator is going to be

built on the rotary switch which is how they are assembled in professional audio devices.

By placing the components on the switch (and not on a separate

circuit board with extended wiring), you greatly minimize inductance

of connecting wires and EMI of bundled cabling. Stray

inductance affects the tuned RC networks and are not very welcome!

Once this is assembled then it will be installed in the matrix

switch box to control the audio level going to the monitors, and

that completes the DIY project. It may take a while...

Home